Infrared Curemaster

Shortwave Infrared Paint Curemaster - GT7606WH

Features

|

|

Specifications

| Power supply | 220-240V 50/60HZ 1PH |

| Power rating | 6 x 1100W |

| Curing area | 1800 x 1000mm |

| Number of cassette | 6 |

| Lamp tube | VPower quartz shortwave infrared halogen lamp tube |

| Temperature setting | 40-100℃ |

| Timer | 0-60min |

| Supporting post | Aluminum alloy |

| Control system | Fully automatic overload protection. Equipped with digital display. |

|

|

| Equipped with shortwave infrared double-layer halogen lamp tube that is specifically designed according to the requirements of curing body paint with advantage of well-distribution of heat energy, curing more effective and gentle light intensity. Double-layer and explosion-proof light tube enables to prevent the damage of paint surface caused by the breakage of emitter |

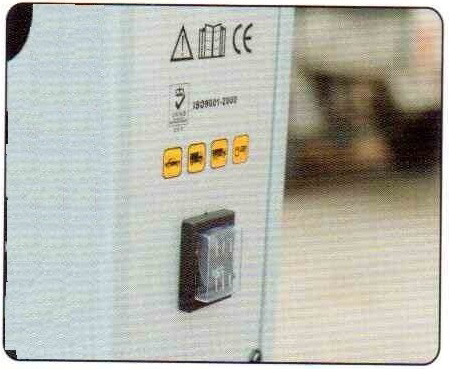

Control system with PET hot press molding technique and touch-key panel design provides high stability and durability. Time and temperature can be shown simultaneously by the dual-window digital display of control system for accurate settings according to body paint requirements. |

|

|

| With integrated design, the entire structure of cassette including the side panel is die-cast by aluminium alloy to ensure the most effective heat release and durable. |

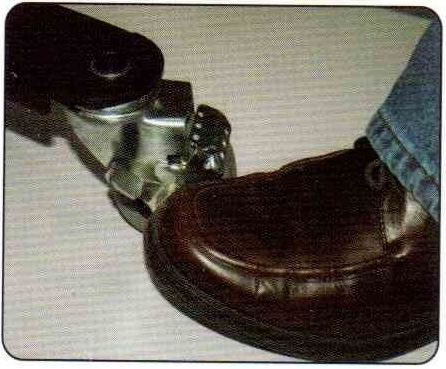

Easy movement of the system. Heavy-duty caster with brake in order to fix the system in position. |

|

|

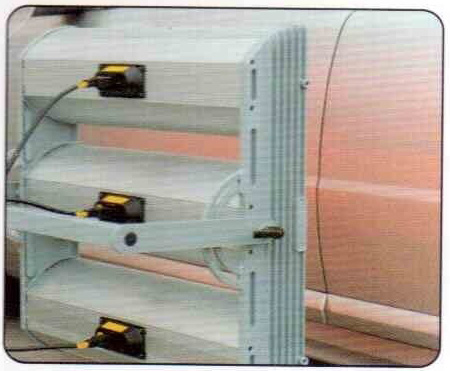

| Two sides of cassette complete with inside and outside aluminium alloy universal locking system. | Tight fitting electrical plug and socket at the rear of case with safe and reliable. |

|

|

| Cassette can be rotation. | Waterproof power switch for safety. |

Perfect union of practicality and technique - We created a reliable and high-effective equipment. It can reduce your total cost in paint curing.

Generally speaking, the higher the temperature, the shorter the wave length produced. The difference between the three types-long, medium and short, is in the depth of penetration through the paint film (in automotive applications) and excitement of the molecular structure. The advantage of using infrared is that only heats objects that are placed in its path, directly focusing energy where it's needed. Infrared equipment causes molecular excitement both in the paint and in the substrate which in turn causes heat to pass back through the coating via conduction. The use of shortwave infrared is in fact triggering a two way curing using radiated energy from the surface and conduction from the substrate and it is this effect that produces such good through curing. Shortwave produces high temperature that dramatically accelerate the curing/drying process. Unlike traditional method, the cured paint could not be skinned, trapping solvent that will produce solvent pop (a pinhole effect) to the finish. Another benefit is that infrared is much more efficient that convection, and it is this combination of fast, high quality curing with low running costs.